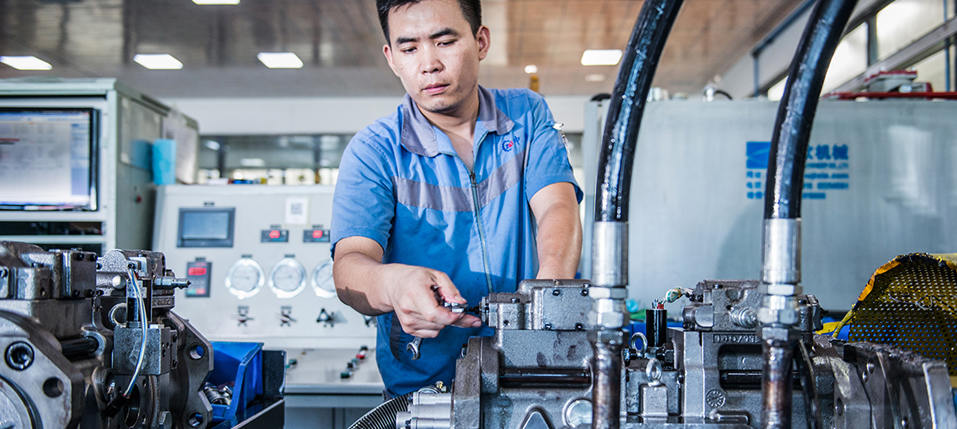

Surface requirements and processing of hydraulic parts

The cylinder barrel is the main component of the oil cylinder, mining single pillar, hydraulic support, gun barrel and other products. The quality of its processing directly affects the life and reliability of the entire product. The cylinder has high processing requirements, and its inner surface roughness is required to be Ra0.4 ~ 0.8µm, and the requirements for coaxiality and wear resistance are strict. The basic feature of the cylinder barrel is deep hole machining, which has always troubled the processing personnel. The rolling process, because the surface layer has residual compressive stress on the surface, helps to seal the tiny cracks on the surface and hinders the expansion of erosion. Thereby, the corrosion resistance of the surface can be improved, and the generation or expansion of fatigue cracks can be delayed, thereby improving the fatigue strength of the cylinder. Through rolling forming, a layer of cold work hardening layer is formed on the rolling surface, which reduces the elastic and plastic deformation of the contact surface of the grinding pair, thereby improving the wear resistance of the inner wall of the cylinder and avoiding burns caused by grinding. After rolling, the reduction of surface roughness value can improve the fit properties. As the control hub of the hydraulic system, the hydraulic valve moves frequently, and has very high requirements on the precision, sealing and reliability of each component device. Most foreign companies use rolling to improve the precision coordination.