At present, R-rings have basically become standard on Rexroth industrial valves, and have achieved good results in the food, pharmaceutical processing and plastic machinery industries that have strict requirements on leakage.

So, why choose R-rings instead of the commonly used O-rings?

The R-ring has a large contact area, and the heat generated during the movement is difficult to dissipate, so it is generally only used for static sealing;

However, the additional advantage is that the contact pressure of the sealing surface of the O-ring is uniform and thus has better stability.

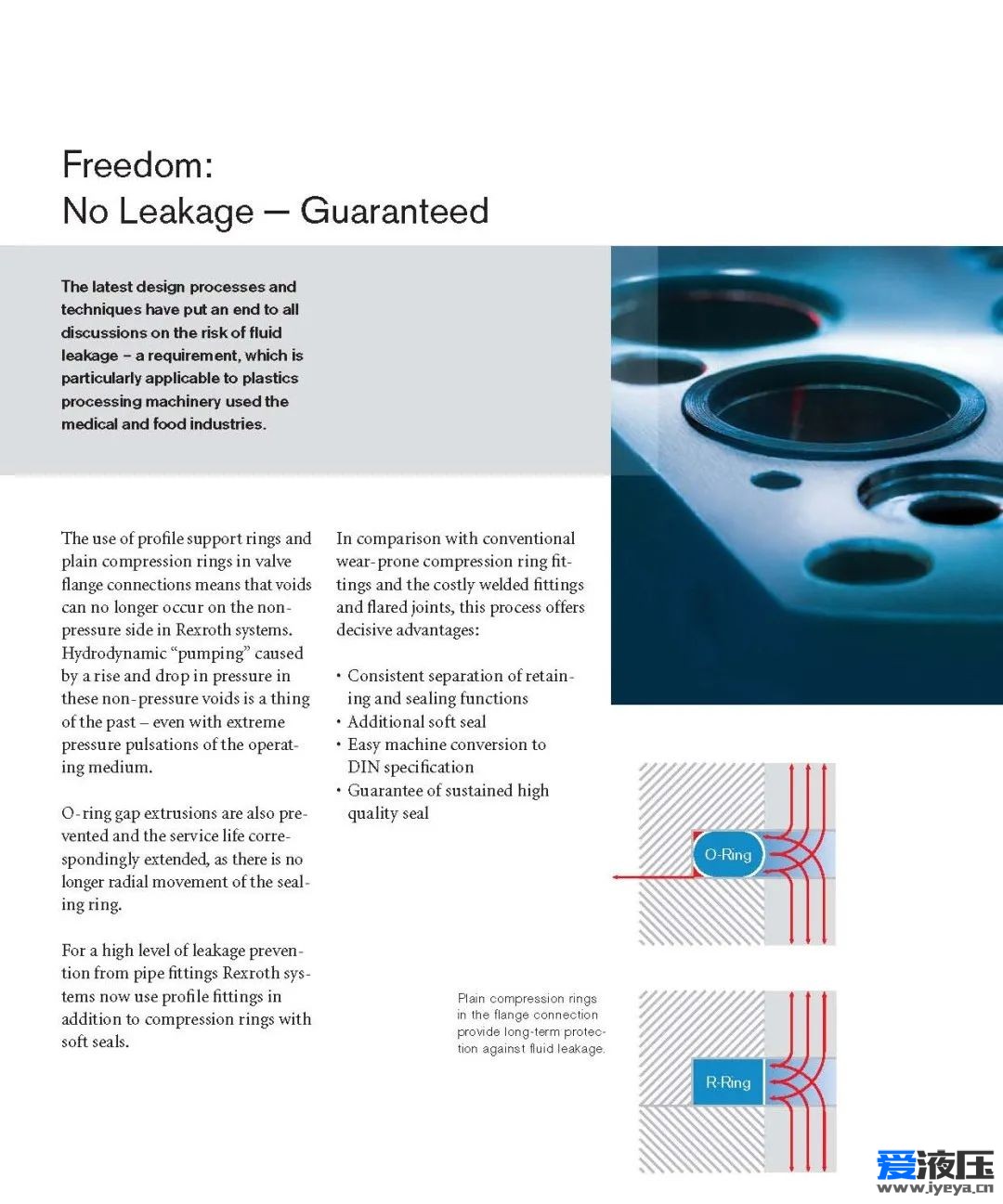

Compared with the O-ring, the R-ring can effectively reduce the radial movement in the plane seal, thereby effectively reducing the oil leakage caused by the pumping phenomenon caused by the pressure fluctuation. Although the slight deformation caused by pressure fluctuations may cause the oil and vapor to slowly cross the sealing line formed by the O-ring, it is difficult to cross the sealing ring surface formed by the R-ring, which is equivalent to the cascade arrangement of countless sealing line clusters, which makes the oil and vapor leakage unsustainable. It is thus possible to guarantee zero leakage from here.

Because the original single line seal of the O-ring has become the current surface seal of the line cluster, the service life of the seal is greatly extended.

In addition, because there is no need to worry too much about the sealing ring being siphoned into the hole, the installation groove of the R-ring does not need to be provided with a chute like the O-ring, which makes the processing complicated.